You are here

camloc products used in NASA applications according to NASA requirement: SSP 57000 Revision R

- English

- Français

- Nederlands

- Español

- Deutsch

- Português

camloc products are specified by Anemo Engineering for NASA applications due to NASA requirement: SSP 57000 Revision R

We are working at this very moment on two exciting projects:

1) 3D printing is the future in space

a machine now exists that makes 3-D printed items back into plastic filament. it's some kind of recycler.

The recyler is then paired with a 3-D printer and can be used in the International Space Station.

to give you a rough idea about the cost of such machine (around 750000 USD)

this project specifically called upon NASA requirement: SSP 57000 Revision R

the big challenge in space is:

- weight

- very small tighterning torque for the fastener 13.73 Nm (or the astronauts are turned when they actuate the fastener)

- typical used material = stainless steel

This is an experiment to see how many times you can recycle plastic in the microgravity environment before the polymers break down

Firmamentum’s plastic-recycling process, known as Positrusion, was the focus of earlier experiments funded by NASA’s Small Business Innovation Research program, or SBIR

Another company, already has built 3D printers that went into use on the space station. These 3-D printers melt down plastic filament and deposit tiny squirts of the stuff in a computer-controlled pattern to produce tools and other objects. The Refabricator would advance the state of the art by combining a 3-D printer with a Positrusion system that can turn 3-D-printed items back into plastic filament. Such a system would come in handy during a human mission to Mars. This capability will enable the astronauts to use material that would otherwise be waste to maintain their spacecraft and adapt to unforeseen challenges on the Martian surface

For example, if an astronaut had a Refabricator,

he can easily recycle his food trays and other plastic waste into the tools and parts he needs to survive, and ‘The Martian’ would have been much less of a nail-biter

off course I am very hopeful that it has a significant terrestrial market

small note on the tightening torque: (opening torque is the highest) (it is advised to use installation tool 4P3-1 so spring gets compressed during installation

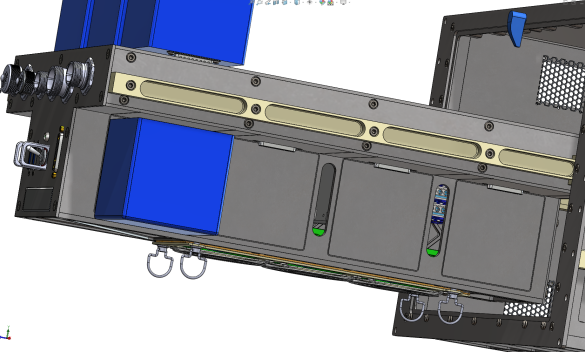

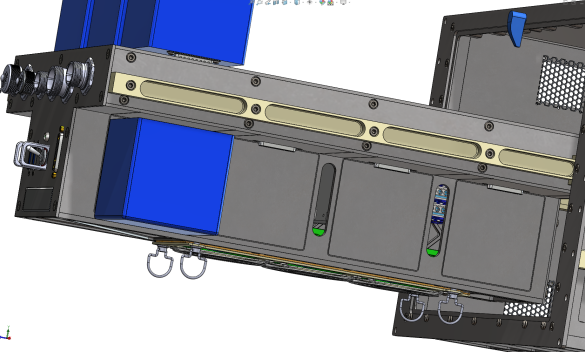

2) International Space Station project European Columbus Module on-board the International Space Station project - ESA, European Space Agency

they will use a fastener that is newly developed inside the ISS.

this time a zinc plated fastener is okay: V26S22-11AGV which is a folding bail handle, so astraunates do not harm themselves once the fastener is operated.

They do not need a tool to operate it, which is handy in space, and also can fold the handle so that the whole assembly fits back in the tray.

The ISS is one of the best achievements of our era. This one of its kind laboratory is providing science results from its birth, and will continue doing so for the next years. Commercial access to ISS for research, technological demonstration and educational projects has been offered by NASA during the last years. Now is the time for the European Space Agency who is launching strategical partnership with several private companies. The first one with a facility on board will be Space Application Services thanks to ICE Cubes.

The nominal size of an experiment to be fitted on the ICE Cubes facility is a 10cm cube (same form factor of a cubesat), but several cubes can be put together. COTS can be used inside the cubes, and users can design and build their experiment what reduces considerably the costs. Once on board, telemetry and comanding capabilities will be offered in near real time. The standard service comprises: Certification, launch, installation and power and data access to the cube.

About Space Applications services:

Space Applications Services is an independent Belgian company founded in 1987, with a subsidiary in Houston, USA. Their aim is to research and develop innovative systems, solutions and products and provide services to the aerospace and security markets and related industries. Their activities cover manned and unmanned spacecraft, launch/re-entry vehicles, robotics and a wide range of information systems.

Anemo Engineering has developed together with Space Applications the project to integrate camloc fasteners.

products selected are V26S22-11AGV with retaining washer V2600-LW-7 and receptacle V26R6-1AGV

it's showing that you do not need camloc quarter turns to be made of stainless steel, in the inside of the space shuttle

Camloc is a registered brand name of Howmet Aerospace.

Camloc is a registered brand name from ![]()